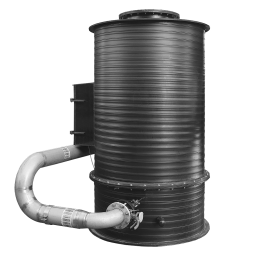

Description

The SH S-KAT is a round PE container (1200mm dia.) with a mineral filling medium that has a very large inner and outer surface on which bacteria can live and convert the H2S into sulphate,

which is then removed from the reactor through a siphon, together with the process water. At less than € 50 per year, the operating costs of the SH S-KAT are extremely low. It is also easy to integrate with an existing system.

Plus, there is no need for a gas drying system with a heat exchanger and an expensive air conditioner, because the biogas doesn´t require drying. The SH S-KAT system is also used to reduce the activated carbon costs or eliminate the need for iron salts.

BENEFITS

· easy to integrate

· negligible operating costs of less than € 50 per year per S-KAT

· no need for gas drying

· maintenance interval: only 1-2 times a year

· higher volume flows possible due to parallel operation

· small footprint

· no activated carbon

· no iron additives = biology in the fermenter is not disturbed

FIELDS OF APPLICATION

The S-KAT is suitable for plants with lower or higher volumeflows (parallel operation).

· biogas plants (new and existing plants)

· landfill gas plants

· waste recycling

BUILDING TYPES

· cylindrical design

MATERIAL

· PE

References

References (H2S reduced to <10 ppm):

Volume flow

250 m³/h

125 m³/h

50 m³/h

500 m³/h

500 m³/h

180 m³/h

H2S cargo

200 ppm

400 ppm

800 ppm

200 ppm

400 ppm

1.500 ppm

Quantity of plants

1 S-KAT

1 S-KAT

1 S-KAT

2 S-KAT

3 S-KAT

4 S-KAT